-

Palm oil refinery

Palm oil fractionation plant

Palm oil fractionation plant

Palm oil fractionation means to control cooling crystallization process to separate palm oil to 3 parts: palm stearin, palm olien and palm midfraction. -

Palm oil press

Palm oil processing line

Palm oil processing line

Palm oil processing line gathering palm oil making, palm oil refining, and palm oil fractionation processing lines, ensures high efficiency and high oil yield of edible palm oil. -

Palm oil refinery

Palm oil cooling and crystallization eqipment plant

Palm oil cooling and crystallization eqipment plant

Cooling and crystallization are key palm oil fractionation process. Once crystallization successes, palm oil separation becomes easily. Therefore, different type of crystallization should have own cooling exchange surface. -

Palm oil press

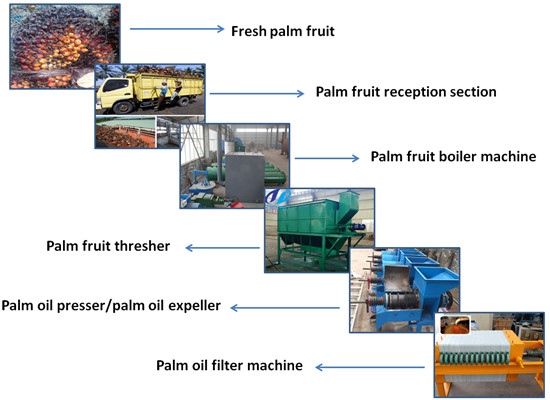

Palm oil mill procesing plant

Palm oil mill procesing plant

We company is professional palm oil mill procesing plant manufacturer.We provide complete palm oil production plants and customized service.We are able to offer a range of professionally designed palm oil pressing refining machine . -

Palm kernel oil expeller

Palm kernel oil production line:pressing and refi

Palm kernel oil production line:pressing and refi

Henan Doing Company is professional palm oil production machine manufacturer.We provide complete palm kernel oil production plants and customized service.We are able to offer a range of professionally designed palm kernel oil pressing machine. -

Palm oil press

Red palm oil extraction process

Red palm oil extraction process

This article is aimed to give a brief description of how palm oil is extracted. Palm oil is an edible oil, derived from the flesh of palm fruit. In the unprocessed form it has a bright red color and is solid. -

Palm oil press

60-100 tons FFB/h palm oil milling machine

60-100 tons FFB/h palm oil milling machine

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process,The capacity of mills varies between 60-100 tons FFB/h. A typical mill has many operation units . This comprises sterilization, stripping, digestion and pressing. -

Palm oil refinery

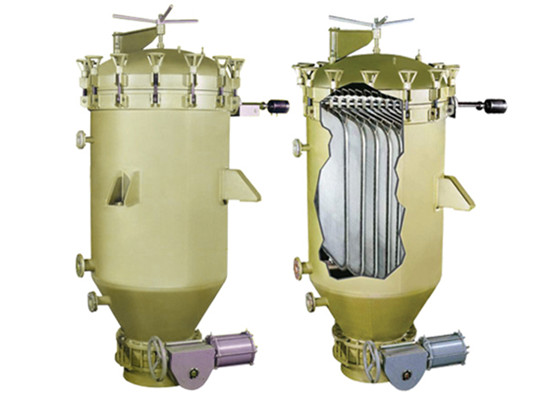

Palm oil filtration machine

Palm oil filtration machine

Palm Oil Filtration selection is extremely important for improving yield of liquid palm oil during palm oil fractionation process. Currently industrial filtration system contains drum filter,plate frame filter, and vertical leaf filter.