What are the different types of small scale palm oil refinery plants available?

Looking to dip your toes into the palm oil refining business without high upfront costs? Batch-type small scale palm oil refinery plants are your ideal starting point—featuring the advantages of a low investment threshold, simple and flexible operation, and the ability to easily switch between processing multiple crude oil varieties, they let you easily turn raw materials into high-quality, market-ready edible palm oil.

Below are two customized batch-type palm oil refinery plants from Henan Glory, tailored to different production needs and capacity ranges, helping you select the ideal solution for your needs.

1. Electric Heating Batch-Type Palm Oil Refinery Plant

This type is designed for small-batch production with a processing capacity of 0.5-2tpd, which adopts resistance wire heating for precise control of refining temperatures. It features low initial investment and rapid heating response, making it ideal for small-scale, on-demand production. However, it has relatively high requirements for local voltage stability, coupled with high power consumption, which results in higher long-term operational costs.

Electric heating palm oil refinery plant

Electric heating palm oil refinery plant

2. Thermal Oil Heating Batch-Type Palm Oil Refinery Plant

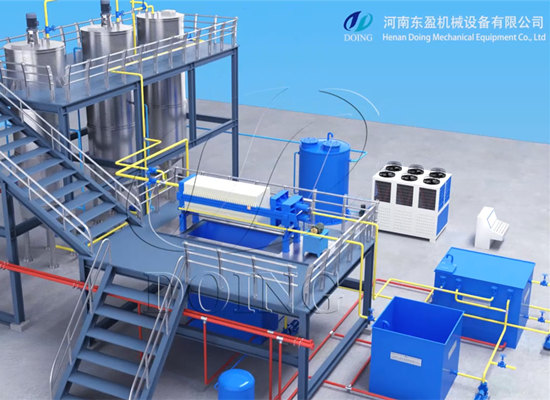

With a processing capacity ranging from 1-20tpd, this palm oil refinery plant uses thermal oil furnaces for indirect heating, ensuring consistent temperature control throughout the refining process and effectively avoiding oil quality fluctuations caused by uneven heating. It is more economical in long-term operation, which is suitable for small businesses that plan to moderately expand production scale and pursue stable oil quality output.

Thermal oil heating palm oil refinery plant

Thermal oil heating palm oil refinery plant

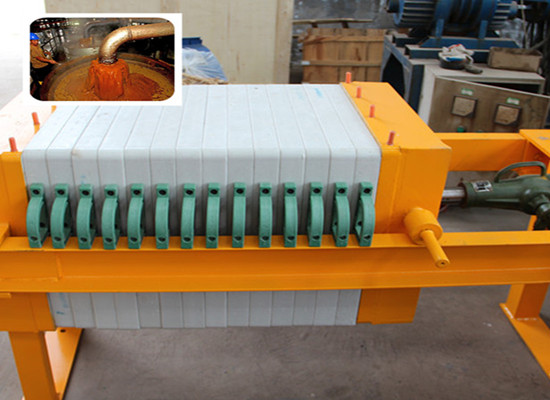

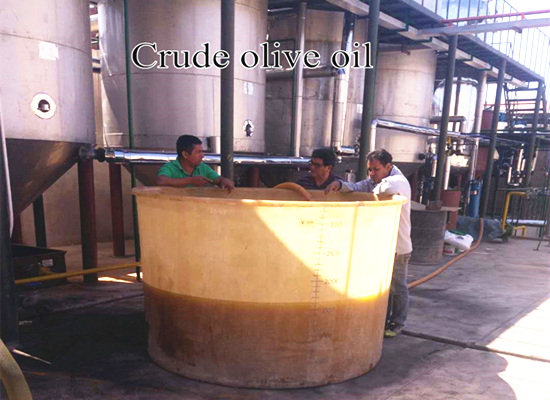

Both of our batch-type palm oil refinery plants rely on a tried-and-tested core process—chemical refining process—to deliver high-quality, market-compliant refined palm oil. The core workflow includes four essential steps. First is degumming, where raw palm oil is treated with phosphoric acid or hot water to remove gum impurities. Next is deacidification, using NaOH solution to eliminate free fatty acids, which will form soapstock that can be further processed for other uses. Then comes bleaching, during which activated clay is added to adsorb pigments and other residual impurities, followed by filtering out the spent bleaching clay. The last essential step is deodorization, removing peculiar smells from the oil via steam under negative pressure conditions.

Ready to find the perfect palm oil refinery plant for your business? Contact us today—we'll provide personalized consultation, detailed technical parameters, and tailored quotes to help you start your palm oil refining project smoothly.

Leave A Message About What are the different types of small scale palm oil refinery plants available?

palm oil refinery plant projects

palm oil refinery process video

-

Small scale palm oil refining and filling machine operation video

-

-

Continuous palm oil refining and fractionation machine 3D animation (part 2)

-

Continuous palm oil refining and fractionation machine 3D animation (part 1)

-

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation

-

Indonesia 5tpd palm oil refinery plant successfully installed video

-

-

-

-

Video for decolorization and deodorization process of palm oil