Continuous palm oil refinery plant

Factory direct sale contact number

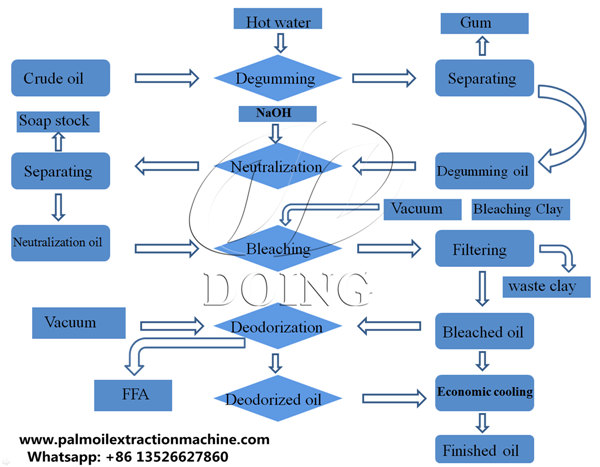

According to the palm oil production process and different capacity , palm oil refinery plant can be divided into intermittent palm oil refinery plant (batch type palm oil refinery plant )and continuous palm oil refinery plant . In general,Batch type palm oil refinery plant can process crude palm oil with capacity 1-30tons. And we recommed continuous palm oil refinery process for 30tons and above capacity. But the processes in each palm oil refinery plant are almost the same. The complete palm oil refinery process includes degumming process, deacidification process, decolorization process, deodorization process and so on.

Basic process of continuous palm oil refinery plant is same with batch type palm oil refinery plant. Only difference is instead of refining palm oil batch by batch, the whole palm oil refinery process if full continuous, no need much human operating,suitable for bigger capacity above 30tpd.

Continuous palm oil refinery plant

Basic stages of the continuous palm oil refinery process are as below:

Degumming ;

Deacidification (Neutralizing);

Bleaching;

Deodorization;

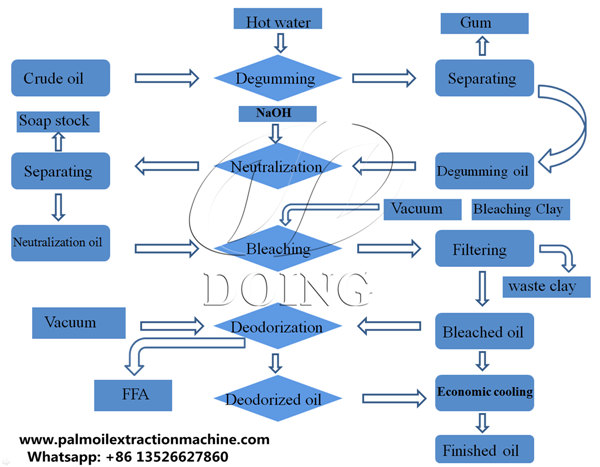

Continuous palm oil refinery process flow chart:

Continuous palm oil refinery process flow chart (Click here to view larger diagram)

Note: Main equipment: Crude oil filter, Crude oil tank, Crude oil pump, Washing centrifuge,Degumming centrifuge,Vacuum dryer, Hot water tank,Soap-stock tank,Decolorization tower,Decolorization oil pump,Plate filter, Steam super-heater,Decolorizing oil tank, Deodorization tower,Deodorization oil pump,Vacuum system, Vacuum pump, Cooling tower, Thermal oil furnace, PLC automatic control

Detail introduction of continuous palm oil refinery plant:

Palm oil deacidification process (also named palm oil neutralization process)

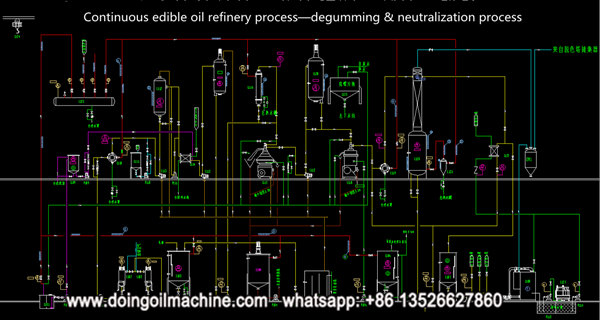

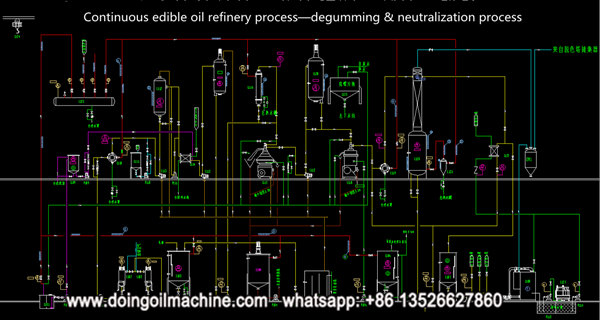

Continuous palm oil refinery process flow chart ---palm oil degumming & deacidification process diagram

(1) Neutralization section

During the neutral section, put the degummed palm oil with appropriate temperature and the appropriate concentration of alkali liquor into the centrifugal mixer, in order to achieve the best effect, the mixture is then sent to neutralization tank for enough time, in the process, liquid alkali saponification soap free fatty acid formation, and within the neutralization separator is separated.Formation soapstock also played an adsorption oil soapstock other impurities, and the function of color pigment.In order to enhance the separation effect, the mixture of oil/soap in neutralizing heater is heated to reduce its viscosity.

(2) Washing process:

The separated Neutralized oil still contains about 500 ppm soap; In order to reduce the residual content of soap, oil is joined by about 5% of hot water, and washed in the washing mixer, hot water will absorb oil soap and other impurities, remaining in the water separator are then separated.

(3) Vacuum drying section:

Output oil from the water washing neutralizing and washing oil separator, still contains some unfavorable to the stability of remaining water, in order to remove the residual moisture, oil was about 110-120 degrees, was taken to the tower of vacuum drying/desolventizing dehydration, drying oil is pumped directly into the decoloring process.

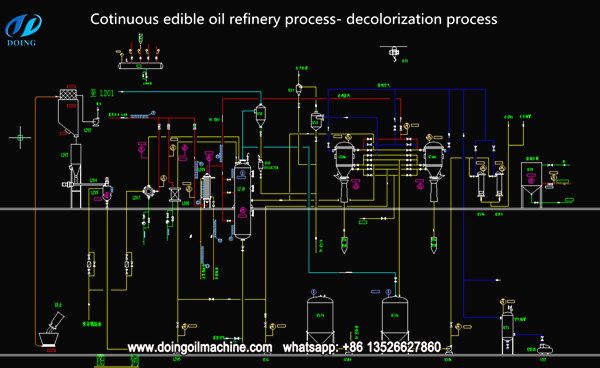

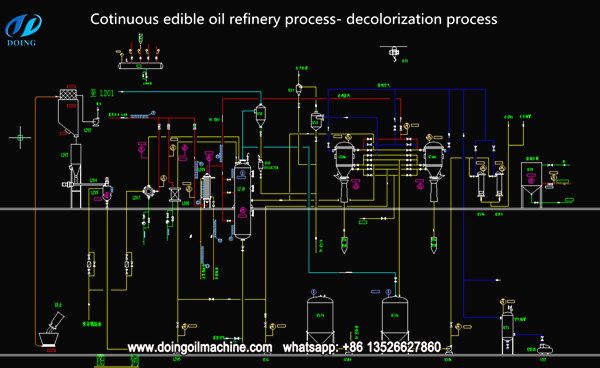

Palm oil decolorization process( palm oil bleaching process)

Continuous palm oil refinery process flow chart ---palm oil decolorization process diagram

The decolorization section aims to remove pigment existed in the crude oil, soap residue in the oil and so on. PaLm oil decolorization process includes the following stages:

a: Decoloration

Under steady flow control, oil uses low pressure steam and oil heater heating to 105 degrees. The heated oil is then sent to the vacuum bleaching tower.When oil enters the bleaching tower, mix with the clay through a mix ratio. Clay transport system used in the ground between the white folk to the clay storage, flowing into bleaching tower above of storage tanks.Bleaching tower is separated into several layers, each layer is equipped with a steam ejector, which is used for mixing oil and clay, the residual soap in the oil, gum precipitation, plastid and other metals has also been absorped by the bleaching earth.

b: Filter:

Oil from bleaching tower, mixed with clay, then pumped into the decoloring filter, and then enter the fine filter, clay and solid impurity is blocked here, filter (decoloring oil) is then transferred to the decolorizing intermediate storage tank.

Two decoloring filters are in this system, there is always one filter in filtering state, the other is in a state of empty and clean. When in the period of emptying and cleaning filter pressed by steam, so most of the oil in the filter is blowed to the decoloring oil tank, a small number of oil mixed with clay was discharged into steam cyclone and slop tank, filter cake blow dry steam; In the filter drying period, slop tank is also filling with leftover oil and condensate, finally the dry cake is at the bottom of the filter through the discharge valve, making use of pneumatic vibrator is fallen into the waste clay room.

The rest slop is pumped back to bleaching tower and be reprocessed.

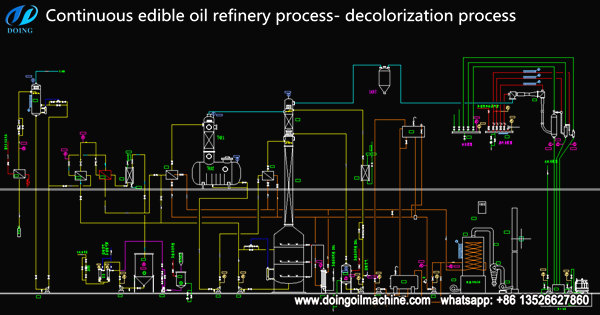

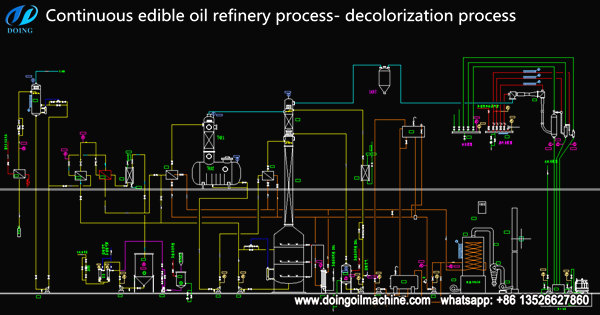

Palm oil deodorization process:

Continuous palm oil refinery process flow chart ---palm oil deodorization process diagram

Deodorization section aims to remove free fatty acids, small molecules that exist in the decoloring oil material, etc. It includes the following stages:

a: deaerator

From filter decoloring oil is stored within the decoloring oil tank, the tank is designed to work in the vacuum condition; from this tank, decoloring oil is pumped into the vacuum state analysis of the deaerator, release out the empty air in the oil.

b: Heat:

Entering the deodorization period of decoloring oil flow rate is controlled by a flow controller, oil is through a series of heat exchangers and heated to about 250-200 degrees of deodorization temperature:

When oil is heating in the final oil heater, part of the free fatty acids of low boiling point here and some of the volatile matter is evaporated, gas and liquid oil enters into the padding type deodorization tower from different entrances.

c: Deodorization:

After heating oil in flash tower, main deodorization tower, retention tank to distillation, vaporization and odor components of fatty acid in oil are removed.

d: Fatty acid recovery

In the washing area, the recycling of free fatty acid distillate flowing downwards from the top, which is often used to condensat rising free fatty acids and other condensate in the air. Condensation of distillates are collected in the temporary storage tank, the fatty acids are recycling: cooling in fatty acid distillates cooler, then recycled to the top of the fatty acids trap. Fatty acids temporary storage tank of liquid level is controlled by manual.

To reduce the quantity of fatty acid drops within air goes into the vacuum system and circular water pool, we installed a demister on the capture.

e: Heat-exchange and cooling

From deodorization tower, through deodorization pump to raw out the smelly oil, and then through the oil heat exchanger cooling by the incoming of decoloring oil, and then into the oil cooler, cooling by cooling water to the storage oil temperature,; finally through the fine filter for fine polishing filter, and then are fed into the product tank.

Photos of continuous palm oil refinery plant:

Continuous palm oil refinery plant

Economic & technical Index of continuous palm oil refinery plant ( degumming, deacidification, bleaching, deodorization)

We are professional palm oil refinery plant manufacturer and supplier, if you have interest in batch type palm oil refinery plant, continuous palm oil refinery plant , please don’t hesitate to contact us . Just telling us what type of oil and capacity , we will quote you best price with advanced oil refining technology and high quality equipment.

Basic process of continuous palm oil refinery plant is same with batch type palm oil refinery plant. Only difference is instead of refining palm oil batch by batch, the whole palm oil refinery process if full continuous, no need much human operating,suitable for bigger capacity above 30tpd.

Continuous palm oil refinery plant

Basic stages of the continuous palm oil refinery process are as below:

Degumming ;

Deacidification (Neutralizing);

Bleaching;

Deodorization;

Continuous palm oil refinery process flow chart:

Continuous palm oil refinery process flow chart (Click here to view larger diagram)

Detail introduction of continuous palm oil refinery plant:

Palm oil deacidification process (also named palm oil neutralization process)

Continuous palm oil refinery process flow chart ---palm oil degumming & deacidification process diagram

During the neutral section, put the degummed palm oil with appropriate temperature and the appropriate concentration of alkali liquor into the centrifugal mixer, in order to achieve the best effect, the mixture is then sent to neutralization tank for enough time, in the process, liquid alkali saponification soap free fatty acid formation, and within the neutralization separator is separated.Formation soapstock also played an adsorption oil soapstock other impurities, and the function of color pigment.In order to enhance the separation effect, the mixture of oil/soap in neutralizing heater is heated to reduce its viscosity.

(2) Washing process:

The separated Neutralized oil still contains about 500 ppm soap; In order to reduce the residual content of soap, oil is joined by about 5% of hot water, and washed in the washing mixer, hot water will absorb oil soap and other impurities, remaining in the water separator are then separated.

(3) Vacuum drying section:

Output oil from the water washing neutralizing and washing oil separator, still contains some unfavorable to the stability of remaining water, in order to remove the residual moisture, oil was about 110-120 degrees, was taken to the tower of vacuum drying/desolventizing dehydration, drying oil is pumped directly into the decoloring process.

Palm oil decolorization process( palm oil bleaching process)

Continuous palm oil refinery process flow chart ---palm oil decolorization process diagram

a: Decoloration

Under steady flow control, oil uses low pressure steam and oil heater heating to 105 degrees. The heated oil is then sent to the vacuum bleaching tower.When oil enters the bleaching tower, mix with the clay through a mix ratio. Clay transport system used in the ground between the white folk to the clay storage, flowing into bleaching tower above of storage tanks.Bleaching tower is separated into several layers, each layer is equipped with a steam ejector, which is used for mixing oil and clay, the residual soap in the oil, gum precipitation, plastid and other metals has also been absorped by the bleaching earth.

b: Filter:

Oil from bleaching tower, mixed with clay, then pumped into the decoloring filter, and then enter the fine filter, clay and solid impurity is blocked here, filter (decoloring oil) is then transferred to the decolorizing intermediate storage tank.

Two decoloring filters are in this system, there is always one filter in filtering state, the other is in a state of empty and clean. When in the period of emptying and cleaning filter pressed by steam, so most of the oil in the filter is blowed to the decoloring oil tank, a small number of oil mixed with clay was discharged into steam cyclone and slop tank, filter cake blow dry steam; In the filter drying period, slop tank is also filling with leftover oil and condensate, finally the dry cake is at the bottom of the filter through the discharge valve, making use of pneumatic vibrator is fallen into the waste clay room.

The rest slop is pumped back to bleaching tower and be reprocessed.

Palm oil deodorization process:

Continuous palm oil refinery process flow chart ---palm oil deodorization process diagram

a: deaerator

From filter decoloring oil is stored within the decoloring oil tank, the tank is designed to work in the vacuum condition; from this tank, decoloring oil is pumped into the vacuum state analysis of the deaerator, release out the empty air in the oil.

b: Heat:

Entering the deodorization period of decoloring oil flow rate is controlled by a flow controller, oil is through a series of heat exchangers and heated to about 250-200 degrees of deodorization temperature:

When oil is heating in the final oil heater, part of the free fatty acids of low boiling point here and some of the volatile matter is evaporated, gas and liquid oil enters into the padding type deodorization tower from different entrances.

c: Deodorization:

After heating oil in flash tower, main deodorization tower, retention tank to distillation, vaporization and odor components of fatty acid in oil are removed.

d: Fatty acid recovery

In the washing area, the recycling of free fatty acid distillate flowing downwards from the top, which is often used to condensat rising free fatty acids and other condensate in the air. Condensation of distillates are collected in the temporary storage tank, the fatty acids are recycling: cooling in fatty acid distillates cooler, then recycled to the top of the fatty acids trap. Fatty acids temporary storage tank of liquid level is controlled by manual.

To reduce the quantity of fatty acid drops within air goes into the vacuum system and circular water pool, we installed a demister on the capture.

e: Heat-exchange and cooling

From deodorization tower, through deodorization pump to raw out the smelly oil, and then through the oil heat exchanger cooling by the incoming of decoloring oil, and then into the oil cooler, cooling by cooling water to the storage oil temperature,; finally through the fine filter for fine polishing filter, and then are fed into the product tank.

Photos of continuous palm oil refinery plant:

Continuous palm oil refinery plant

Economic & technical Index of continuous palm oil refinery plant ( degumming, deacidification, bleaching, deodorization)

| Power consumption | ≤28 KWH/ton oil |

| Steam consumption | ≤360~420 Kg/ton oil |

| White earth consumption | ≤8~20 kg/ ton oil |

| Caustic soda | ≤7 kg/ ton oil(according to crude oil acid |

| Phosphoric acid | ≤1.0 kg/ ton oil |

| Water consumption | Circulating water 60~65t/h |

| Water consumption 0.25~0.3t/ton oil |

We are professional palm oil refinery plant manufacturer and supplier, if you have interest in batch type palm oil refinery plant, continuous palm oil refinery plant , please don’t hesitate to contact us . Just telling us what type of oil and capacity , we will quote you best price with advanced oil refining technology and high quality equipment.

Leave A Message About Continuous palm oil refinery plant

palm oil refinery plant projects

Palm oil refining technology FAQ

-

Crude palm oil refining methods and palm oil refining process flow chart

Crude palm oil refining methods and palm oil refining process flow chart

-

What is a Palm Oil Refinery?

What is a Palm Oil Refinery?

-

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

-

How much it will cost to set up a palm oil refinery plant?

How much it will cost to set up a palm oil refinery plant?

-

How does the palm oil refinery plant works?

How does the palm oil refinery plant works?

-

What are the different types of small scale palm oil refinery plants available?

What are the different types of small scale palm oil refinery plants available?

-

A guide to the equipment for crude palm oil refinery

A guide to the equipment for crude palm oil refinery

-

What steps make up the palm oil refining process?

What steps make up the palm oil refining process?

-

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

-

How poor palm oil deodorization design can affect your profits?

How poor palm oil deodorization design can affect your profits?