Batch type palm oil refinery plant

Henan Doing Company is a leading manufacturer and exporter of batch type palm oil refinery plants and occupies a prominent place. All the palm oil refinery plants designed and supplied by us have the low-operating cost and deliver the excellent refining solutions.

A batch type palm oil refinery plant is the most widely used system to refine different oils. This type of palm oil refinery process is generally used for smaller capacity plants ranging from 1 Tons Per Day to 30 Tons Per Day. The batch oil refining system is preferred because it is low cost and quite easy to operate. This makes the batch palm oil refinery process economical, low capital oriented and more viable for use up to 30 TPD.

Batch type palm oil refinery plant

Batch type palm oil refinery plant

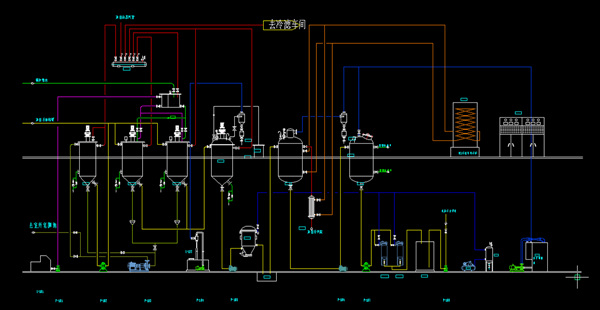

Batch type palm oil refinery process flow chart:

Palm oil refinery process flow chart (click here to view larger view)

Palm oil refinery process flow chart (click here to view larger view)

Description of Batch Type Palm Oil Refinery Process: (Following are the basic processes of batch type palm oil refinery plant:)

Degumming & deacidification Section

The crude oil is pumped to refining pot from storage tank & it is treated with weak solution of suitable hot water and Phosphoric acid for removing gums. Refining pot are used to remove the FFA by adding alkali liquor. Oil is heated by heating coils and stirred. The chemical reaction forms the soap stock. It is later settled and collected after several hours. The oil is then washed to remove traces particles and free alkali.

Bleaching Section ( decolorization section)

Neutral oil is heated in the decolorization machine to remove excess moisture and color. It is also treated with measured quantity of earth. After several hours of controlled process, the oil passes through a filter media to separate the spent earth. Oil obtained after bleaching is light in color and has good appearance.

Deodorization section:

The deodorization process removes odor from the oil to improve the quality of oil. The clean bleached oil is heated in deodorizer pressure vessel to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated at high temperature for several hours under vacuum and steam is allowed to release. Entire process is under high vacuum and high temperature.

Cooling Process

The deodorized oil needs to be cooled at the atmospheric temperature to avoid oxidation. The deodorized oil is cooled in the heat exchanger cooler. The circulating coils take away the heat and the oil is cooled.

After cooling it will pass through polishing filter to obtain sparkling light color & odorless oil.

Once the process cycle is complete the palm oil obtained will be RBD palm oil. This can be used for packing or as final edible oil for cooking.

Batch type palm oil refinery plant manufacturing site:

Batch type palm oil refinery plant manufacturing site

Batch type palm oil refinery plant manufacturing site

Batch type palm oil refinery plant installation site:

Batch type palm oil refinery plant installation site

Batch type palm oil refinery plant installation site

Batch type palm oil refinery plant installation site

Batch type palm oil refinery plant installation site

Available Capacity for bacth type palm oil refinery plant:

1-TPD, 3-TPD, 5-TPD, 10-TPD, 15-TPD, 20-TPD, 30-TPD

Related palm oil machine:

1-10tpd small scale palm oil refinery plant

Continuous palm oil refinery plant

Palm oil fractionation plant

Henan Doing Company supplies batch type palm oil refinery plants with latest technology giving pure, refined, consistent and stable finished oil at output! Get in touch with us!

PREV:Nothing

PREV:Nothing

Leave A Message About Batch type palm oil refinery plant

palm oil refinery plant projects

Palm oil refining technology FAQ

-

Crude palm oil refining methods and palm oil refining process flow chart

Crude palm oil refining methods and palm oil refining process flow chart

-

What is a Palm Oil Refinery?

What is a Palm Oil Refinery?

-

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

-

How much it will cost to set up a palm oil refinery plant?

How much it will cost to set up a palm oil refinery plant?

-

How does the palm oil refinery plant works?

How does the palm oil refinery plant works?

-

What are the different types of small scale palm oil refinery plants available?

What are the different types of small scale palm oil refinery plants available?

-

A guide to the equipment for crude palm oil refinery

A guide to the equipment for crude palm oil refinery

-

What steps make up the palm oil refining process?

What steps make up the palm oil refining process?

-

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

-

How poor palm oil deodorization design can affect your profits?

How poor palm oil deodorization design can affect your profits?