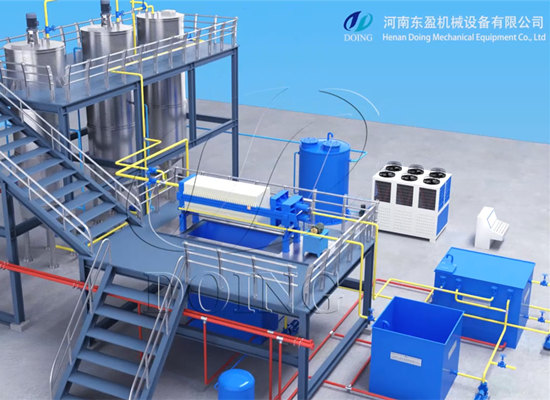

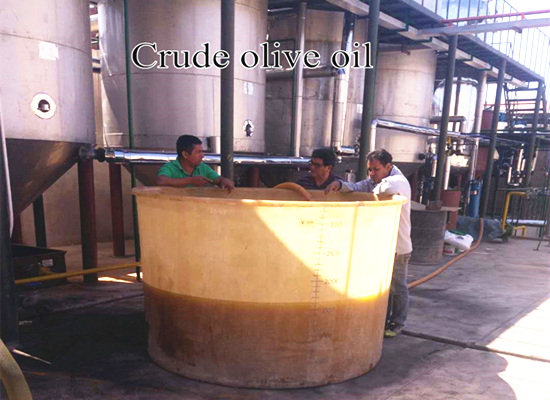

palm oil refinery plant projects

palm oil refinery process video

-

Small scale palm oil refining and filling machine operation video

-

-

Continuous palm oil refining and fractionation machine 3D animation (part 2)

-

Continuous palm oil refining and fractionation machine 3D animation (part 1)

-

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation

-

Indonesia 5tpd palm oil refinery plant successfully installed video

-

-

-

-

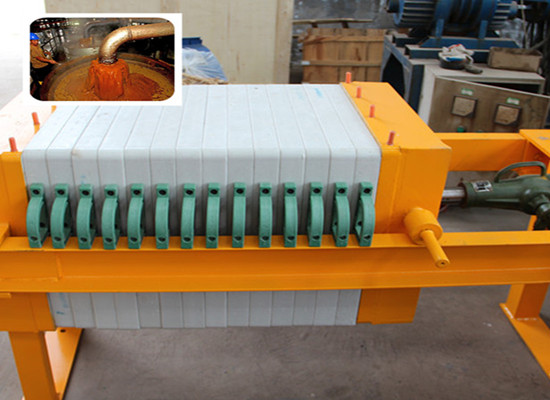

Video for decolorization and deodorization process of palm oil