Crude palm kernel oil refinery process

Crude palm kernel oil refinery process introduce:

The purpose of palm kernel oil refining is to remove impurities in crude edible oil and reach the standard of finished edible oil. The main palm kernel oil refinery process is: crude palm kernel oil degumming neutralization decolorization deodorization process. During palm kernel oil refinery process, we adopts water hydration degumming, alkali neutralization or steam distillation deacid, adsorbent activated clay or activated carbon decolorization, high temperature and negative pressure deodorization and removal of low boiling point volatile fumes.

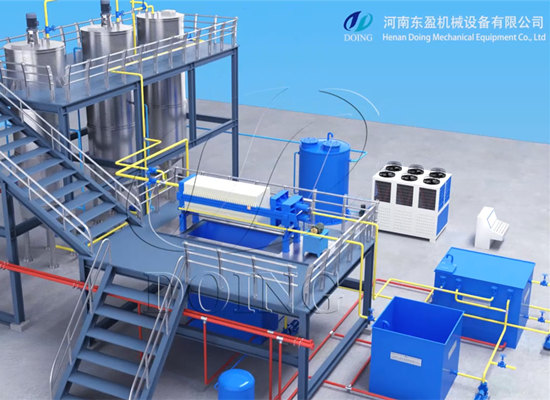

Crude palm kernel oil refinery plant with capacity 30-1000tpd

Crude palm kernel oil refinery plant with capacity 30-1000tpd

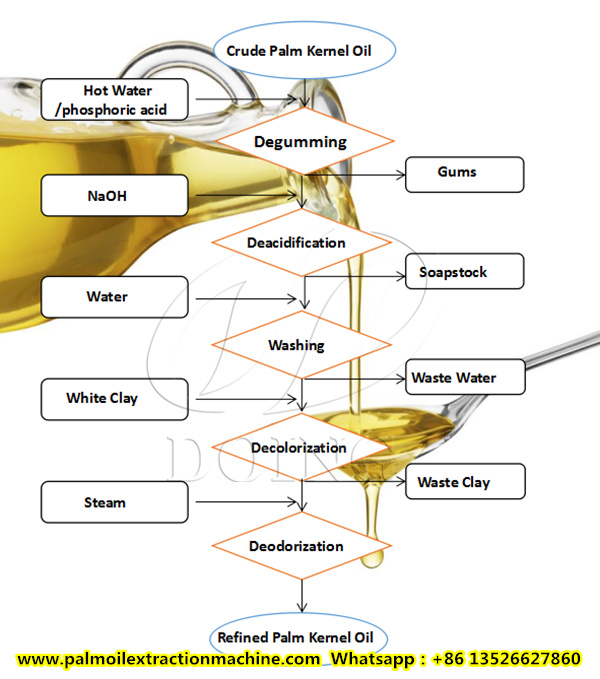

Crude palm kernel oil refinery process flow diagram:

Crude palm kernel oil → Degumming process → Deacidification process → decolorization process → deodorization process → Finished edible palm kernel oil

Crude palm kernel oil refinery process flow diagram

Crude palm kernel oil refinery process flow diagram

Description of crude palm kernel oil refinery process:

Palm kernel oil degumming & deacidification process :

Calibrated crude oil is pumped to pipe filters; then filtered oil is sent to heat exchanger. Heated oil is mixed with acid in the mixer before going to the reaction tank. After reaction and cooling, the oil enters another mixer to mix with caustic alkali liquid to neutralize. The neutralized oil enters the centrifugal to separate soap from oil. Separated oil still contents some quantity of soap that should be removed. By mixing with hot water, the oil is washed. Then a centrifugal is used to separate the water with residual soap from oil

Palm kernel oil decolorization process:

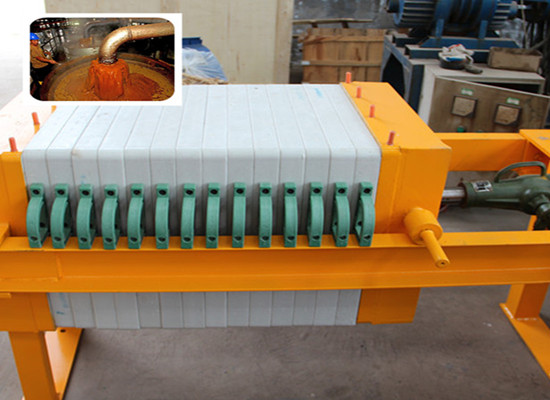

De-gummed and neutralized palm kernel oil is pumped into vacuum drier, and then dried oil is cooled by a heat exchanger and sent into a storage tank. De-gummed and neutralized palm kernel oil is sent to bleaching section to bleach. Oil to be bleached is pumped to mixed tank and heating tank separately. A proportion of oil to be bleached is pumped into a mixing tank to mix with dosed bentonite, and another part of oil to be bleached is pumped to the heater. The mixture and the heated oil go into the bleaching tank to de-colourize. Consequently, the mixture of oil and bentonite is pumped into leaf filter to remove deposable bentonite.

Parallel leaf filters make it possible to perform continuous operation of bleaching. Filtered oil is pumped into the storage tank after being cooled in a heat exchanger and filtered safely.

Palm kernel oil deodorization process:

Deodorization section is to remove the unpleasant odor from bleached palm kernel oil. Certain amount of citric acid liquid is added to the oil to be deodorized to chelate the metal ion in oil. The oil then enters a deaeration tank to remove air in the oil by high vacuum. Then oil is pumped into a heat exchanger to raise temperature with hot deodorized oil; sunflower oil is heated further by mineral oil to raise the temperature to 240℃~265℃. The heated oil goes into the deodorizer tower from the top of flash sector; mixes with the rising steam to strip low molecular organic compound. Oil flows down to the bottom of tower to perform pigment decomposition. The flavor of oil is improved. Oil is pumped into the main sector of deodorizer tower to further remove free fatty acid (FFA). The vapor goes into FFA stripping sector to exchange heat; the condensed low molecular compound goes into the recycling FFA stripping system. The deodorized oil from the bottom of deodorizer tower is pumped out to exchange heat with oil that comes out from the deaeration tank, and then goes to a cooler. Finally, oil is filtered by polished filter. Final product is sent to final oil tank, which can be sold as first class product oil.

From the above introduction , you can know the whole palm kernel oil refinery process, palm kernel oil refinery process operation specification. Any questions, please contact Henan Doing Company!

Leave A Message About Crude palm kernel oil refinery process

palm oil refinery plant projects

palm oil refinery process video

-

Small scale palm oil refining and filling machine operation video

-

-

Continuous palm oil refining and fractionation machine 3D animation (part 2)

-

Continuous palm oil refining and fractionation machine 3D animation (part 1)

-

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation

-

Indonesia 5tpd palm oil refinery plant successfully installed video

-

-

-

-

Video for decolorization and deodorization process of palm oil