What's the common equipment for small scale palm oil refinery plant?

In terms of quality, color and smell, refined palm oil performs better than crude palm oil. In order to get more profits, many novices want to start with small scale palm oil refinery plant to refine crude palm oil, but they don’t know much about what common equipment they should purchase. Therefore, I would introduce the common equipment for small scale palm oil refinery plant and hope it is helpful to you.

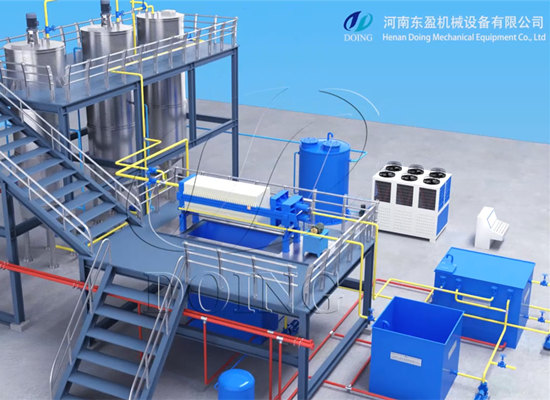

The common equipment for small scale palm oil refinery plant is batch type palm oil refinery equipment. There are mainly two kinds of batch type palm oil refinery equipment, one of them is equipped with electric heating system, and the other is equipped with thermal oil heating system. And they have different equipment lists.

The batch type electric heating palm oil refinery equipment involves the main following equipment: refinery tank, decolorization tank, deodorization tank, steam generator, box filter and other equipment. While the batch type thermal oil palm oil refinery equipment mainly involves refinery tank, decolorization dank, deodorization tank, steam generator, thermal oil furnace and other equipment.

Electric heating and thermal oil heating palm oil refinery equipment

Electric heating and thermal oil heating palm oil refinery equipment

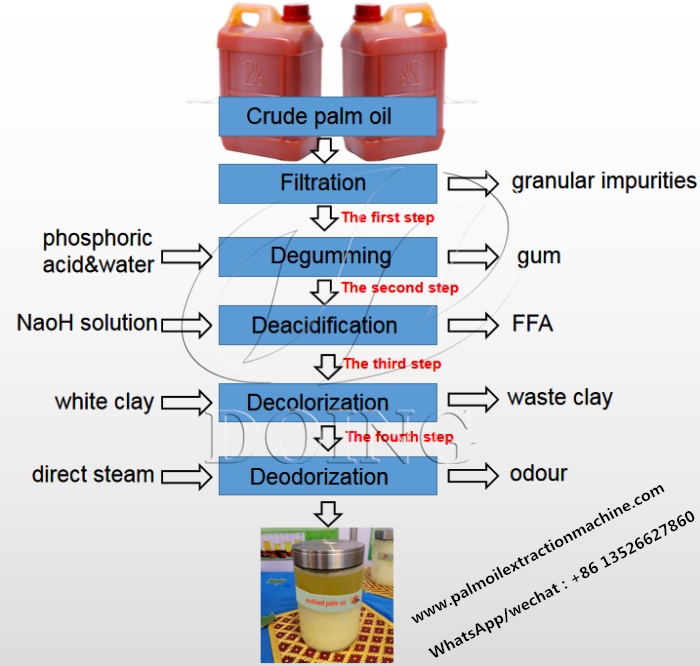

But the processing technology of these two kinds of batch type palm oil refinery equipment is the same. It mainly includes five steps: degumming, deacidification, decolorization, filtration and deodorization.

1.Degumming: Add food grade phosphoric acid to the refinery tank to transform the non hydrated phospholipid into hydrated phospholipid, and add water to make the gum enter the aqueous phase to precipitate and remove.

2.Deacidification: Degummed oil is added with food grade alkaline for acid-base neutralization reaction and removed by heating and natural sedimentation.

3.Decolorization: When the oil is heated to a certain temperature, a certain amount of activated clay and activated carbon are added in the neutralized oil, the pigment in the oil will be physically adsorbed.

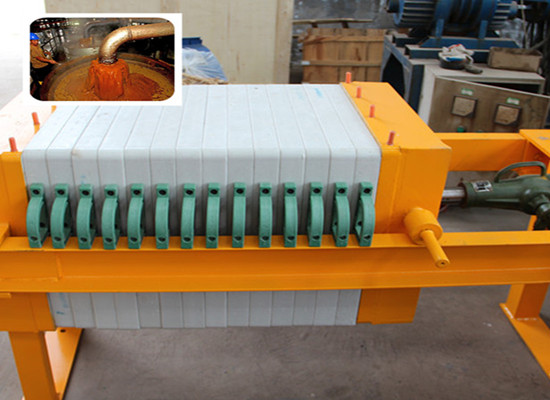

4.Filtration: The solid-liquid mixture of decolorized oil and clay is introduced into the blade filter, and the white clay and oil are separated by the filter plate.

5.Deodorization: Evaporate unpleasant odors and moisture in a high-temperature vacuum environment to obtain refined oil of good quality.

[Recommended reading: Palm oil refining process flow chart and crude palm oil refinery process steps]

Palm oil refining process flow chart

Palm oil refining process flow chart

Our engineers have more than ten years of project experience in palm oil refining, and the quality of the refined palm oil obtained by using our palm oil refinery equipment can meet the national standards. Our projects are spread all over the world, such as the 2TPD refining project in Congo-Brazzaville, the 5TPD refining project in Indonesia, the 100TPD refining project in Kenya and other projects. We can provide the best machines and the best suggestions! Welcome to call us or leave a message!

PREV:How do you purify palm oil and palm kernel oil? What machines are needed?

PREV:How do you purify palm oil and palm kernel oil? What machines are needed?

NEXT:What palm oil purification equipment will be used in palm oil refinery plant?

NEXT:What palm oil purification equipment will be used in palm oil refinery plant?

Leave A Message About What's the common equipment for small scale palm oil refinery plant?

palm oil refinery plant projects

palm oil refinery process video

-

Small scale palm oil refining and filling machine operation video

-

-

Continuous palm oil refining and fractionation machine 3D animation (part 2)

-

Continuous palm oil refining and fractionation machine 3D animation (part 1)

-

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation

-

Indonesia 5tpd palm oil refinery plant successfully installed video

-

-

-

-

Video for decolorization and deodorization process of palm oil