Does palm oil have to be fractionated?

Generally, palm oil can be eaten or used for other purposes. If you just use it as frying oil, palm oil don't have to be fractionated but can be eaten after refining. If you have other purposes like in food manufacturing and processing industries or in the production of soap and oleochemical products, palm oil have to be fractionated. Here, we will talk about two aspects of why palm oil have to be fractionated and what is fractionation specifically.

Why palm oil have to be fractionated for other purposes?

Palm oil contains almost the same amount of SFAs (mainly palmitic acid 44–45%) and unsaturated fatty acids (oleic acid 39–40%, and linoleic acid 10–11%). So, palm oil is associated with human health, especially cardio-vascular diseases (CVDs), and that it has negative effects on the environment. While in some studies it has been suggested that the consumption of palm oil increases low-density lipoprotein cholesterol (LDL-C) more when compared to other vegetable oils, due to its saturated fat content.

The functions of fractionated palm oil

The functions of fractionated palm oil

However, fractionation involves changing the physicochemical features of lipids by physically separating TAGs by selective crystallization and filtration. The principle of this procedure is based on differences in the solubility of solid TAGs in the liquid phase, depending on the molecular weights and unsaturation degrees of TAGs. Therefore, due to its effects on human and environmental health, fractionation, which is considered to be more sustainable as an alternative to the hydrogenization and interesterification processes, is becoming more popular day by day.

What is palm oil fractionation?

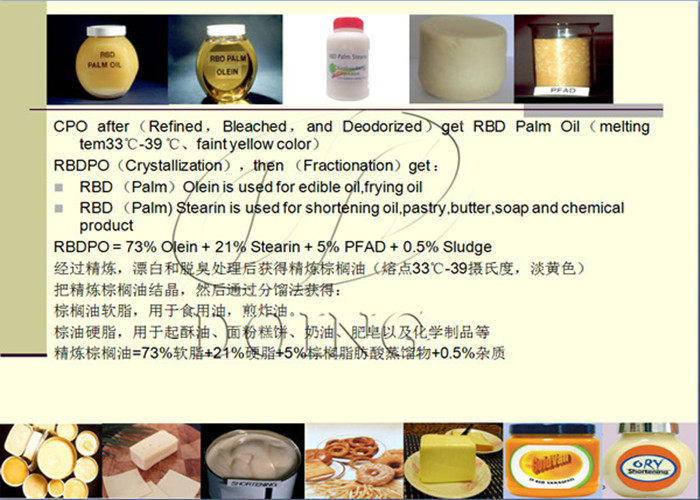

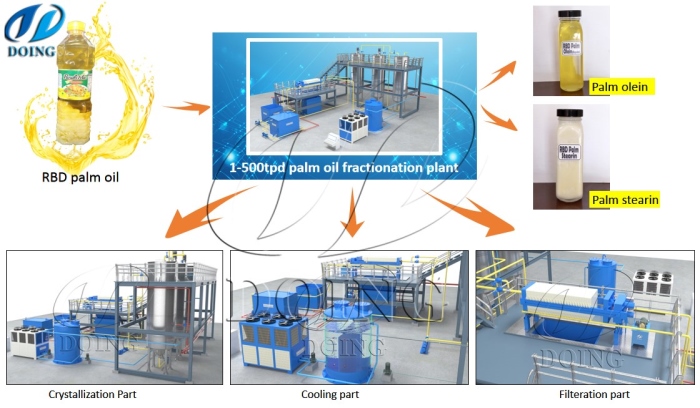

Palm oil fractionation refers to the separation by controlling the cooling and crystallization process of palm oil, which divides palm oil into three parts: stearin, olein and middle part. The melting point of stearin is generally 50°C, and the melting point of olein is generally about 24°C. stearin is suitable for making margarine and cheese oil. olein is a better frying oil. The melting point range of the middle part is narrow and close to human body temperature. , can be used as cocoa substitute fat.

Palm oil fractionation equipment

Palm oil fractionation equipment

For the fractionation method, we use the dry fractionation method the most at present. Dry fractionation is the most economical fractionation method. It refers to the method of slowly cooling the melted oil to the required level without adding other solvents, and then filtering to separate crystals and precipitate solid esters. It is mainly divided into three steps: heating processing, cooling for crystallization and filtration. Usually only one fractionation is required, but for some industries with higher requirements on stearin (confectionary industry, etc.), a second fractionation is required.

The above we introduce why palm oil have to be fractionated and what is palm oil fractionation. We are Henan Doing Holdings Henan Glory Oil & Fats Engineering Co.,Ltd, which is belong to Doing Holding. We are mainly engaged in vegetable oil raw material pretreatment, pressing, refining, solvent extraction, dewaxing, palm oil and palm kernel oil refining, pressing and fractionation, etc. Our company has the most advanced palm oil and edible oil pressing production technology, and undertakes edible oil production lines of various sizes. If you are interested, please contact us.

PREV:Why choose Henan Glory Company's palm oil fractionation plant?

PREV:Why choose Henan Glory Company's palm oil fractionation plant?

NEXT:What is the cost of a 1 ton per day palm oil refining and fractionation plant?

NEXT:What is the cost of a 1 ton per day palm oil refining and fractionation plant?

Leave A Message About Does palm oil have to be fractionated?

palm oil refinery plant projects

Palm oil refining technology FAQ

-

Crude palm oil refining methods and palm oil refining process flow chart

Crude palm oil refining methods and palm oil refining process flow chart

-

What is a Palm Oil Refinery?

What is a Palm Oil Refinery?

-

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

-

How much it will cost to set up a palm oil refinery plant?

How much it will cost to set up a palm oil refinery plant?

-

How does the palm oil refinery plant works?

How does the palm oil refinery plant works?

-

What are the different types of small scale palm oil refinery plants available?

What are the different types of small scale palm oil refinery plants available?

-

A guide to the equipment for crude palm oil refinery

A guide to the equipment for crude palm oil refinery

-

What steps make up the palm oil refining process?

What steps make up the palm oil refining process?

-

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

-

How poor palm oil deodorization design can affect your profits?

How poor palm oil deodorization design can affect your profits?