Home>News>Industry News>How many types of palm oil refining equipment manufactured by Glory Company?

Home>News>Industry News>How many types of palm oil refining equipment manufactured by Glory Company?

How many types of palm oil refining equipment manufactured by Glory Company?

Now more and more people choose to do refined oil business and expand refineries on the basis of their existing crude palm oil pressing plant , or buy crude palm oil from crude oil suppliers for refining. Henan Glory company is oil refining equipment manufacturer with more than 12 years. Some different types of palm oil refining machine will be listed to you from different aspects.

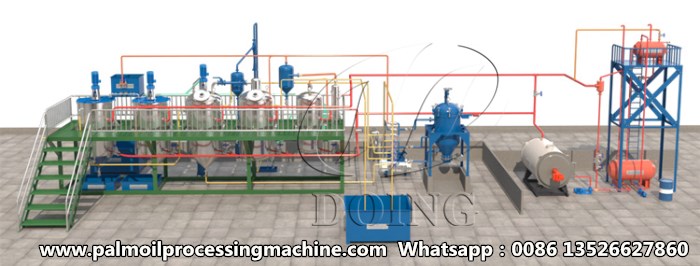

Palm oil refinery plant

Palm oil refinery plant

1. According to different heating methods, it can be divided into electric heating type and refining, and heat conduction oil type.

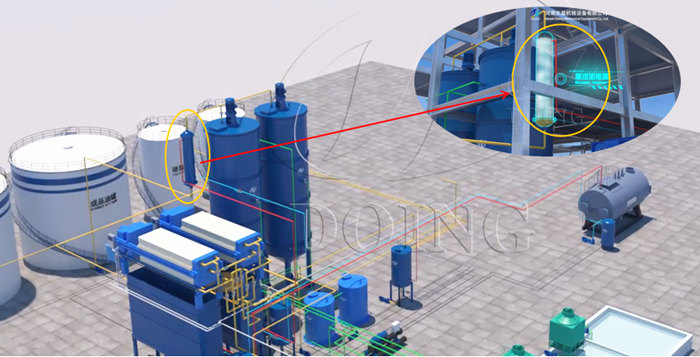

Palm oil heating type

Palm oil heating type

Electric heating refining is suitable for a capacity of 0.5-2tpd. The characteristic is that resistance wire is used to heat crude oil, and the investment is small, but the voltage stability is high and the power consumption is large.

The heat conduction oil type is suitable for processing more than 1 ton. Using thermal oil to heat crude oil requires a thermal oil furnace, but is more economical in the long run.

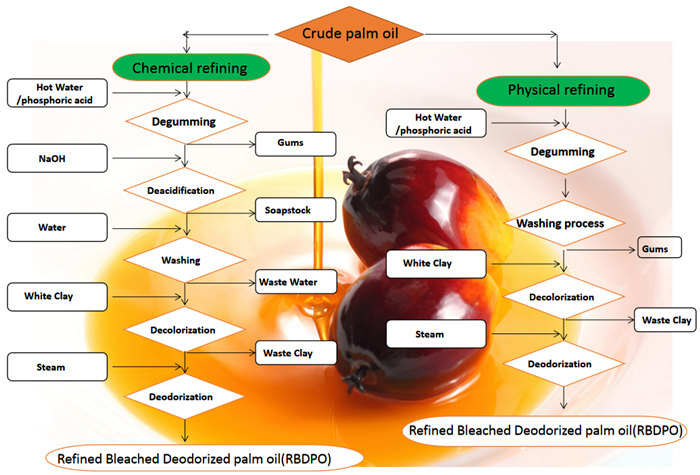

2. According to the classification of refining process, it can be divided into physical refining and chemical refining.

Palm oil physical and chemical refining

Palm oil physical and chemical refining

Generally speaking, physical refining and chemical refining can be distinguished according to whether alkali deacidification is added or not.

Chemical refining: general purpose, suitable for any kind of oilseed.

Physical refining: suitable for oils with low gum content and high acid value, such as palm oil, palm kernel oil, coconut oil, etc.

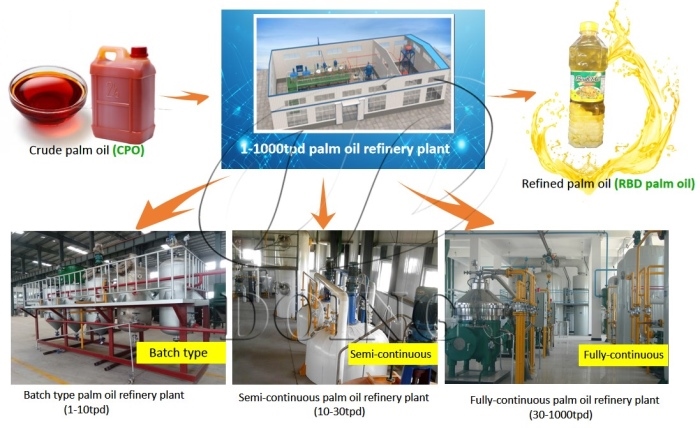

3. According to the degree of automation, it can be divided into batch refining, semi-continuous refining and full continuous refining.

Three types of palm oil refinery plant

Three types of palm oil refinery plant

The refining steps are divided into degumming, deacidification, decolorization and deodorization section.

Batch refining: generally used for refining capacity of ≤20TPD. The advantage of batch refining is that the operation of the equipment is simple and flexible, the investment is small, and it is suitable for frequent replacement of various oil products. The disadvantages are low oil yield, large loss, low work efficiency and unstable product quality.

Semi-continuous refining: generally used for refining capacity of 5-30TPD. In general, the degumming and decolorization section is intermittent production and the deacidification and deodorization section adopts the deodorization tower process for continuous production, which can realize continuous refining, high efficiency, energy saving, economy, and high additional output value.

Full continuous oil refining: generally used for oil refining capacity ≥30TPD. The alkali refining section is equipped with a disc centrifuge, which replaces the natural sedimentation and separation of saponins in the refining pot, and the continuous production of each section of the full continuous refining is uninterrupted. The advantage of this design is that the production consumption is small, the oil loss is low, and the refining quality is more stable.

The above is an introduction about types of palm oil refining equipment Glory Company have. Furthermore, our engineers have more than ten years of project experience about palm oil refining, the technology is very mature, and the quality of the refined oil obtained meets the national standard. If you are need palm oil refining machine, welcome to contact us!

Leave A Message About How many types of palm oil refining equipment manufactured by Glory Company?

palm oil refinery plant projects

Palm oil refining technology FAQ

-

Crude palm oil refining methods and palm oil refining process flow chart

Crude palm oil refining methods and palm oil refining process flow chart

-

What is a Palm Oil Refinery?

What is a Palm Oil Refinery?

-

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

What is palm kernel oil? How to make palm kernel oil, refined palm kernel oil?

-

How much it will cost to set up a palm oil refinery plant?

How much it will cost to set up a palm oil refinery plant?

-

How does the palm oil refinery plant works?

How does the palm oil refinery plant works?

-

What are the different types of small scale palm oil refinery plants available?

What are the different types of small scale palm oil refinery plants available?

-

A guide to the equipment for crude palm oil refinery

A guide to the equipment for crude palm oil refinery

-

What steps make up the palm oil refining process?

What steps make up the palm oil refining process?

-

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

What equipment does a 10tpd crude palm oil refining plant include and how much is the price?

-

How poor palm oil deodorization design can affect your profits?

How poor palm oil deodorization design can affect your profits?